Ideal for the analysis of structures, heat transfers, fluid flows and more, finite element analysis (FEA) is used for both design and litigation purposes in the maritime industry.

Here at Brookes Bell our naval architecture team has extensive experience in the application of FEA which we’ve detailed below.

Structural analysis for design

Brookes Bell regularly uses finite element (FE) computational analyses to evaluate the suitability of structures during design.

Using a parametric approach, our team is able to quickly evaluate the suitability of a large number of iterations of a design.

FEA allows our team to be flexible, as this approach is able to predict the strength and response of a structure with higher fidelity than a simple rule-based calculation. This allows for designers to have greater confidence in the suitability of their designs. It also allows them to evaluate more complex designs than can be assessed with simple calculations.

Structural analysis for forensic investigations

Forensic investigations often turn on how either a component or a large structure failed, or the load at which the failure happened at. In cases of this type, Brookes Bell can help. Structural failures normally result in the exposure of a fractured surface. Our structural experts assess the damage along with our metallurgists and often our other laboratory technicians to determine the type of failure and potential causes. To verify causation, a structural analysis is often needed.

Our experts have an excellent track record of analysing large-scale structural models and validating them with industry-standard software, including:

- ANSYS - engineering analysis software which is used to build and analyse finite element models. This software is also used for CAE/multiphysics engineering simulations

- LS-DYNA - software for analysing dynamic impact simulations

Brookes Bell’s naval architects also have experience conducting a wide range of analysis types for class rule compliance checks and failure investigations, such as:

- Linear analysis for initial assessments and checking rule-compliance

- Linear fracture mechanics for the assessment of cracks or other manufacturing flaws

- Non-linear material analysis for evaluating post-yielding and the ultimate failure of steel components

- Fatigue analysis

- Large-amplitude analysis for buckling and collision failures

- Dynamic analysis for sudden impact loads

We have used finite element analysis in a range of forensic investigations, including:

- The collapse of pressure bulkheads due to fluid pressure

- Large-scale collision damage arising from impact

- The buckling failure of cranes

- The critical defect sizes on large gear teeth

- Fatigue assessment of large gear wheels

- The collapse of hatch covers in green sea loading

Why choose Brookes Bell for your structural analysis?

There are multiple reasons to choose Brookes Bell for your structural analysis requirements:

- We have some of the best experts in the marine forensic investigation industry, with extensive experience giving evidence and writing expert reports

- We bring the best possible analysis tools to bear on challenging problems

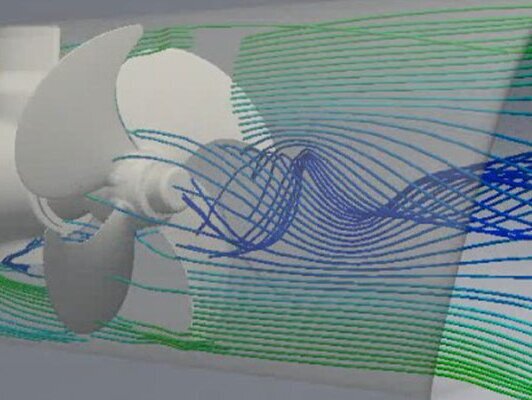

- Marine failures often arise from hydrodynamic pressures where our industry-leading capability in CFD is key

- Our structural analysis experts can form a wider team of metallurgists and NDT experts who will work together to produce the most scientifically-robust analysis

- We understand the need to limit costs and offer solutions to our clients thinking about engaging us for analysis

To find out more about how Brookes Bell’s finite element analysis expertise can help you, speak to us today.