Browse our services

Explore how Brookes Bell can help you

Find an expert

Meet our team, find and expert and connect

Contact us

Get in touch, we're here to help

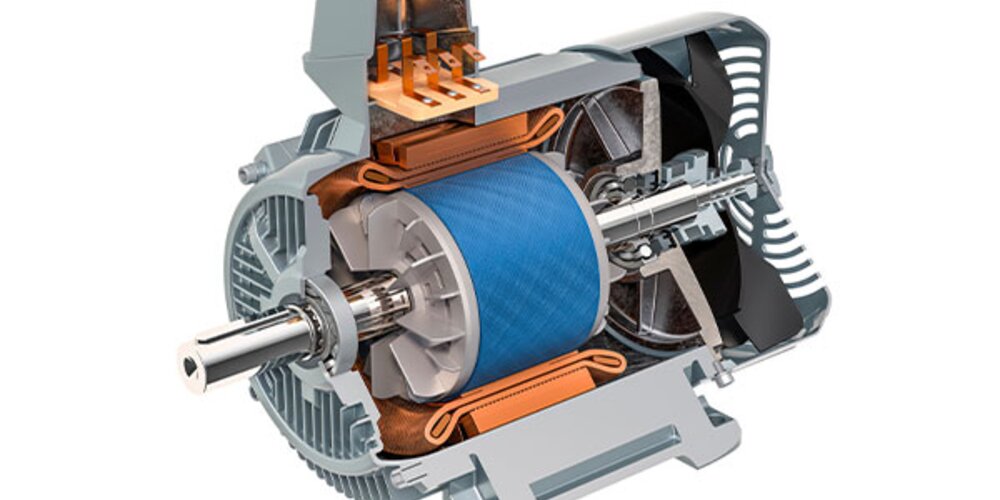

Infinitum - the U.S. based start-up that’s reimagining the electric motor - has revealed its next-generation axial flux propulsion and traction motor. Dubbed ‘Aircore Mobility’, the motor is designed to maximise vehicle range whilst also delivering class-leading efficiency.

So, what’s the big deal? Well, the Aircore Mobility has one feature in particular which differentiates it from traditional electric motors - a printed circuit board (PCB) stator.

Compared to the iron core and copper windings that are used in traditional electric motors, the Aircore Mobility’s PCB stator makes the motor 10 percent more efficient, and 50 percent smaller and lighter.

What’s more, thanks to its PCB stator, the Aircore Mobility motor can achieve up to four to five times the power current density of a conventional, liquid cooled motor.

Aside from offering significant efficiency gains over traditional electric motors, the Aircore Mobility has also been designed with sustainability at the forefront of mind.

The motor can be produced using far fewer raw materials than traditional motors. The Aircore Mobility also has a modular design that allows the housing, rotors and stators to be reused multiple times.

Infinitum also claims that ‘the motor can also be manufactured almost anywhere locally without complex assembly equipment’.

So far, so good. The Aircore Mobility sounds like a significant step forward in electric motor technology. But, can it be practically applied?

According to Infinitum, the Aircore Mobility motor is suitable for a wide range of practical applications, including powering passenger and commercial electric vehicles, agricultural machinery, construction machinery and auxiliary machinery and plant (e.g. HVAC, pumps etc).

Aside from its broad range of practical applications, Infinitum is keen to emphasise the performance and efficiency of the Aircore Mobility - and how this will support the green transition.

Paulo Guedes-Pinto, vice president of technology at Infinitum, explains:

“Our aircore motor topology eliminates core losses and delivers a broader range of speeds and load conditions where the motor can operate at high efficiency levels. The Aircore Mobility motor offers a new avenue in extending range for Class 1–8 vehicles, aerospace, marine, construction, and agricultural machines”.

Infinitum’s Aircore Mobility motor has already come in for praise from a spectrum of sources. For example, Sam Abuelsamid, principal analyst at market intelligence firm Guidehouse Insights, said:

“Infinitum’s motor design using printed circuit board stators offers promising performance and efficiency benefits for mobility applications due to superior heat mitigation and high power density.

With supply chain challenges, the motor’s materials, rapid assembly and scalable production should also be attractive to automotive OEMs seeking dramatically simpler manufacturing going forward”.

Can we expect the Aircore Mobility motor to be embraced and used widely by the maritime industry? It’s perhaps a little early to say, but as always, Brookes Bell will be closely monitoring those developments that can yield significant benefits for our clients.

Trusted by the biggest names in the global maritime industry, Brookes Bell offers a broad range of marine engineering services, covering everything from the forensic investigation of machinery and component failure to expert witness work.

For more maritime industry news, insights and developments, read the Brookes Bell News and Knowledge Hub…

Transport of Lithium-Ion Batteries: A Continuous Threat | What Is Metallurgy and How Is It Used in the Maritime Industry? | Spotlight On: Non-Destructive Testing (NDT)