These sample pages from the Tribology Handbook cover failure analysis of various component types, also design and selection criteria, and lubrication.

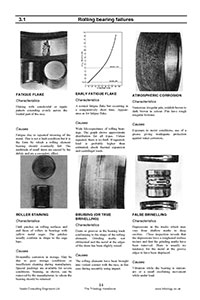

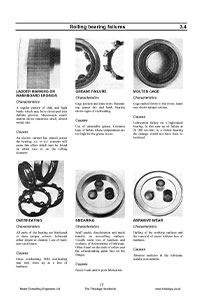

Rolling Element Bearing Failure Analysis

All the typical failure modes and potential causes for rolling element bearing failures. These include such failures as fatigue, corrosion, staining, brinelling, ladder marking, grease failure etc. The final page introduces bearing reliability analysis and L10 life.

Plain Bearing Failure Analysis

Failures associated with plain bearings. In particular, looking at failures from foreign matter, wiping, fatigue, corrosion and erosion of the bearing surface.

Failure Analysis of Gears, Seals, Brakes, Clutches and Wire Ropes

This covers typical failures seen on gears and gear-trains, failures associated with wire ropes and failures typically seen on seals and sealing systems. Also covered are typical failures found on brake and clutches and the final page gives some more information on wear debris analysis.

Material and Lubrication Properties

Pages relating to material selection, lubrication properties of common mineral oils and selection of correct lubrication for particular applications.

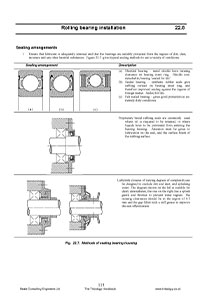

Bearing Selection and Design

The selection of the correct type of journal bearing for particular load and speed applications. Articles then relating to selecting the correct type of rolling element bearing, sizing thrust bearings, and selecting seals. The final article looks at lubrication requirements for rolling element bearings.

If you have not been able to find what you are looking for or need aditional advice or information, please get in touch.